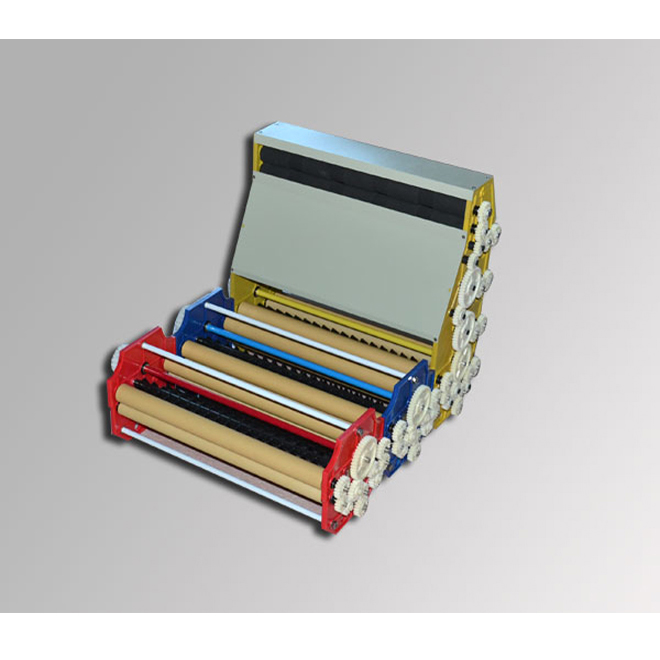

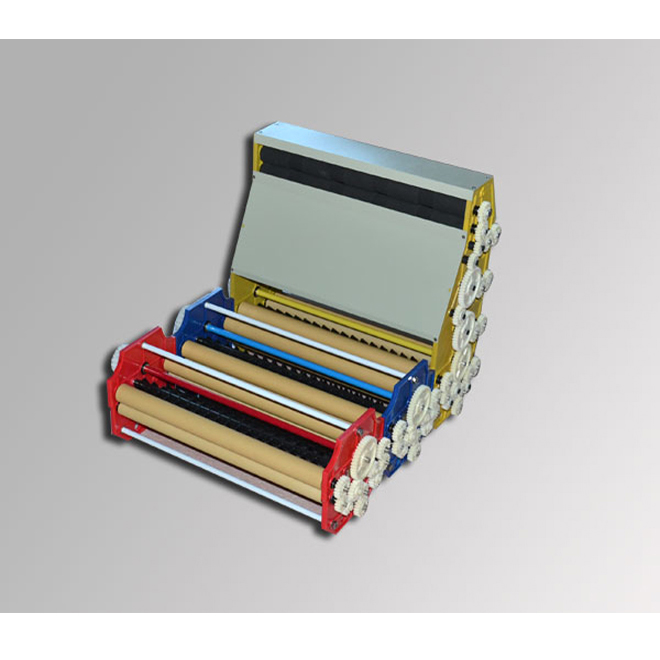

Features of Buy Automatic dental x ray film processor MSLXF14:

1.The function of automatic filling agent

The machine has a design Of fully automatic filling agent function to filling and refilling agent automatically, This function has filled up the bland of functions for medical film processor in local market.lt meets the requirement of doctors,reducing the workload of doctors,and carried out the fully automatic function for medical film processor.

2.Advanced numerical contort electrical circuit

It Chooses the advanced numerical control electrical Circuit to fit up all kindS Of bad envirOnment, It will not only decrease the rate of broken-down, but also make it easy to maintenance, So, it meets the purpose of maintenance easily by everyone and resolves the problem of after-sales service.

3.The new technology of drying tube

The machine takes the great efficient centrifuge and drying tube, it will not only ensure the film fully dry, but aslo the great speed will blow off all of tiny granules form the film.Then,we can get the clean high quality pictures under the high temperature environment.

4.Saving energy automatic being dormant

The saving energy circuit will begin to work automatically when the film stop inputting, then the machine stays on the dormant statement.

5.The advanced roller film input system

The machine installs the non-contact directiOn input system used by imported machines. It will never score the films or jamming the films.

6.The developing temperature and procession the can be adjusted directly

The contrlo panels have the character of knob operation used by imported machines. The temperature of agent and the procedure time can be adjusted without limit.lt is intuitionistic and easy to understand so that it reduces the man-made mistakes.

7.Anti-Oxidation and Anti- Crystal

At the statement Of preparation, working and dormant, the machine will clean the roller automatically so that avoid agent being crystal.

8.The advanced material

The whole machine is made of high quality antiseptic materials, ABS engineering plastic and stainless steel. It is soild and durable .

Specification of Buy Automatic dental x ray film processor MSLXF14:

Development order:Developing―Fixing―Washing

Film size:Min. 3×3 inches Max. 14×17 inches

Film-in style:Photo sensor

Developing time:Adjustable 20s-90s

Developing rate:180(12×15in)/hour

Liquid temperature:Adjustable 23-37℃

Dry temperature:40-70℃

Liquid volume:10L

Liquid transmission:Automatic

Replenishment rate:3L/min

Fluid volume:Automatic replenishment by film detection

Washing style:Tap water

Standby condition:24hours circulation

Environment temperature:0-40 ℃

Environment humidity :RH ≤80%

Power voltage:AC220V±22V ,50HZ±1HZ/13A single phase

Capacity (L×W×H):780×610×1100 (mm)

Weight: 55(Kg)

Client Usage Photos of Buy Automatic dental x ray film processor MSLXF14

Please contact us for more details.

Price is 8-20% Lower Than Other

Price is 8-20% Lower Than Other

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130719/201307191731221107.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20141204/201412041825266247.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130718/2013071816531837.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130717/201307170934409777.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130717/201307171030447609.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130717/201307171705083963.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130719/201307191735528643.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130717/201307171054192245.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130717/201307170920247423.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130903/201309032335403273.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130717/201307171541172444.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130717/201307171117258365.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130719/201307191747553871.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130719/2013071917394427.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130717/201307171133107517.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130717/201307171109565764.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20180108/201801081513557594.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130724/201307241044382007.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130717/201307171656003135.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20130719/201307191752085016.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20191225/20191225120935610.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20191225/201912251215434977.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20200131/202001312221141819.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20200807/202008071419166074.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20200807/202008071428121769.jpg.jpg)