1. PRP centrifuge machine MSLBC02 Technical description

PRP&Fat Purification Centrifuge, operates on the principle of centrifugal sedimentation for the separation, purification or concentration of solution with different density particles.

The centrifuge consists of housing, centrifugation chamber, drive system, control system and operating display panel, including rotors and tubes as accessory.

2.PRP centrifuge machine MSLBC02 Technical Features

centrifuge, equipped with brushless motor, computer controller, door safety device etc. for simple operation, is widely used in the fields of biochemistry, radio immunity, environment protection, Chinese & western pharmaceutical for particles separation with different density.

3.1 PRP centrifuge machine MSLBC02 Technical Data

1、Max. Speed:4000r/min

2、Capacity:4×50ml

3、Max. RCF(field):4390xg

4、Time Range:0~99min

5、Noise:≤65dB

6、Speed control accuracy:±50 r/min

3.2 PRP centrifuge machine MSLBC02 Installation Requirements

a). The centrifuge should be placed on the firm table with four feet contacting the table.

b). Certain space should be allowed around the centrifuge for idea ventilation

c). Power: AC 220V 50Hz 10A with socket capacity >10A,ground connection should be secured.

3.3 PRP centrifuge machine MSLBC02 Normal Working Conditions

a). Environment temperature:5℃~35℃;

b). Relative Humidity:≤85%;

c). The centrifuge operating room should be free from Conductive dust,explosive or corrosive gas

d). Power:AC 110V±22V 50Hz±1Hz,and separate ground connection should be provided in the centrifuge operating room

4. PRP centrifuge machine MSLBC02 Operation

4.1 Rotor Installation

Rotor should be checked carefully before using. It is forbidden to use the rotor and buckets with crack and corrosion spots (especially the bucket bottom of swing rotor).All accessories should not be used if it is exceeding of its service life. The conical surface of driving shaft should be smeared with some lubricating grease if the main spindle is leaving unused.

The drive spindle in the chamber and the inside cones of rotor should be first wiped with a piece of soft and clean cloth, then place the rotor with two hands to the cone side of the drive spindle in the centrifuge chamber, Washer should be placed before tightening the screw nuts.

Warning: The conical surface of rotor and driving shaft must be connected closely.

As shown in the following figure: Firstly clasp the symmetric spoke of rotor, and put it on the rotor base vertically and placidly while the rotor bottom’s location cone aims at the location cone of drive shaft; then put the flat gasket on the lead screw and screw down the cap nut. At last, hold up the rotor steadily (not shacking) by one hand, and put the solid wrench on the cap nut by another hand. In the mean while turn the wrench for 3 to 6 rounds in clockwise direction until the rotor connects the drive shaft closely.

4.2 Installation requirements

Place centrifuge on a steady platform or table. Make four rubber cushions stand in balance to prevent vibration. Otherwise, add some pads to readjust the height up to the requirements (by user).

4.3 Adjusting requirements

Checking the goods

Check the packing list and make sure if damage is occurred during delivery.

Installation, adjustment and maintenance should all be guided or operated by professional technicians.

4.4 Installation of Brackets and Tubes

Place the brackets into the slot of rotor; make sure that the bracket is turning smoothly, tube Sets(adaptors) are placed into holes of brackets, the solution to be separated into the tubes. Visually check if the solution in the tubes is roughly equal before putting them into the tube Sets

can contain the syringe directly, pls refer the following operate picture

Step 1: Change the syringe rod into steel rod.

Step 2: Collect the fat from body then taking down the steel rod and put on the syringe cap, set into the centrifuge rotor.

Step 3:Set the running speed at 1000rpm and centrifugal time 8min. Centrifugal for 2 times can get the high purity fat, and then inject the needed place.

5. PRP centrifuge machine MSLBC02 Safety Notice

a). CONFIRM button should be pressed after speed is Set.

b). The centrifuge will not be allowed to operate under any condition if the speed exceeds the rated speed for the rotor and brackets.

c). The rotor or tube is prohibited for further use if any corrosion or crack occurred.

d). The door will not be allowed to open when the centrifuge is under operation.

e). If the rotor is not in use for three months, it should be subjected to operating for 10 min before it can be allowed to operate at its max speed.

6. PRP centrifuge machine MSLBC02 Maintenance

a). Dry the centrifuge chamber, rotor and tube with a piece of clean and soft cloth after operation.

b). Check regularly to find if there is any corrosion or crack on the rotor, bracket, tube Sets and tubes.

c). If the centrifuge will not be in use for a month, take out the rotor from the chamber, grease the cone side of drive spindle and the cConfirm hole of the rotor, and keep the rotor in a dry plac

7. PRP centrifuge machine MSLBC02 Trouble Shooting

1. No power indication after the machine is powered on:

a). Check if the power supply is OK.

b). Check if the plug and sockets are well connected.

c). Check if the fuse is burned. The correct size of the fuse is F10A250V(Φ5×20);

d). Check if the power indicator is burned.

2. After power on, the power indication is OK, but the operation of machine is abnormal:

a). Check if the time or speed is Set .

b). Check if the control circuit is normal.

3. Abnormal vibration occurred after Starting the machine:

a). Check if there is any foreign materials in the tube Set, check if the solution in the tubes are properly arranged.

b).Check if the tube Set of swing rotor is properly contacted with the bracket.

Beauty equipment supply store hot sale spa equipment

MSL TEAM picture

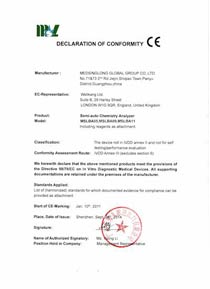

MSL Certificate

MSL Medical cooperate with DHL,FEDEX,UPS,EMS,TNT,etc.International shipping company,make your goods arrive destination safely and quickly.

Price is 8-20% Lower Than Other

Price is 8-20% Lower Than Other

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20170817/201708171832337281.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20170410/20170410182339382.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20161202/201612021755497308.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20180326/201803261736568971.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20170710/201707101756419680.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20171130/201711301129023381.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20160616/201606161747318941.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20190613/20190613162422648.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20170925/201709251756356852.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20161202/20161202174221350.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20180614/201806141724351169.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20161012/20161012114218315.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20190613/201906131623123996.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20160607/201606071446209816.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20190613/201906131626196177.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20161012/201610121056039060.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20161202/201612021736391584.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20170503/201705031533161229.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20180531/201805311519338602.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20190613/201906131621462561.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20190613/201906131630018872.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20170721/201707211811355651.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20170426/201704261819269751.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20170724/201707241620055.jpg.jpg)

![{pr0int $v['title']/}](https://medicalequipment-msl.com/upload/img/20160607/201606071153359954.jpg.jpg)